Balfour employees at the letter jacket facility in Waco, TX, have been sewing masks for local hospitals. They were crafted from cap and gown fabric from Gaspard, Balfour’s sister company, also owned by Iconic Group. Photo by Amanda Reynolds

As shelter-in-place orders temporarily close businesses, Balfour Waco employees transform cap and gown material into medical masks.

Maritza Vaquero is still sewing every day.

On a normal day, Vaquero sits at a sewing machine, adding patches, chenille letters and embroidered names to letterman jackets. But this isn’t a normal day.

Vaquero is still sitting at her sewing machine, but instead of her station in the Waco, TX, letter jacket facility, she’s at a fold up table in her living room. Instead of banners and patches, she’s transforming cap and gown fabric into medical masks.

Maritza Vaquero works from her living room, creating hospital masks out of cap and gown material. Vaquero has worked for Balfour for 15 years. Photo contributed by Maritza Vaquero

Vaquero and a small group of Balfour employees are using their time and skill to create masks for local hospitals.

“[I’m] happy because I know that they will help a lot, and my work will benefit people I do not know,” Vaquero said. “We all need to do our best to be safe from this virus.”

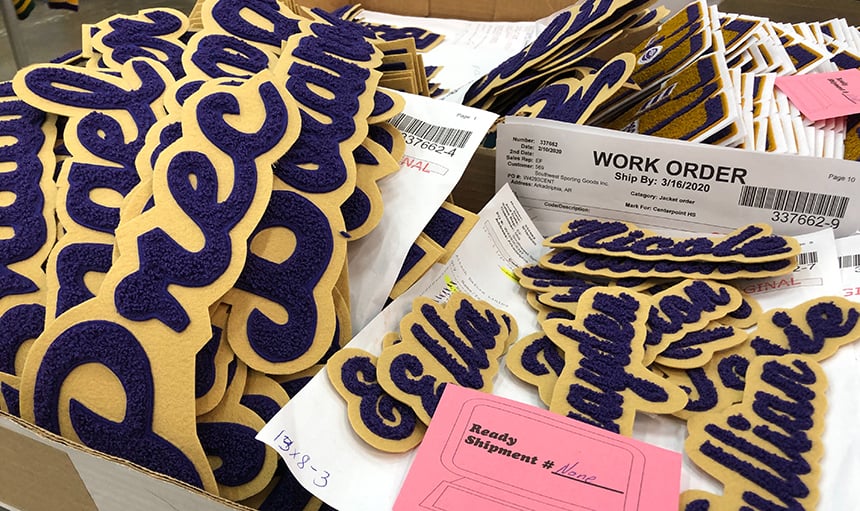

The Waco facility employs 90 people, creating championship and award banners and letterman jacket accessories. They sew patches, chenille names and individual chenille letters as well as embroider names. With McLennan County, where Waco is located, under a shelter-in-place order through April 30 that closed the facility, employees began to look for ways to help during the pandemic.

(Top) A letterman jacket for a Louisiana student features a chenille individual letter on the front and three softball patches on the arm. A batch of chenille names at the Waco letter jacket facility. Photos by Amanda Reynolds

Vaquero and another employee were sewing masks at home when Balfour asked if anyone was interested in assisting. Fabric was ordered from the Gaspard cap and gown facility in Puerto Rico. A trickier problem was the elastic, which is in short supply because of global demand for masks.

“That was the hard part to get,” procurement and inventory manager Diane Mason said. “We could get all the fabric in the world we wanted.”

With the blue cap and gown material, the Puerto Rico facility sent some elastic and more was found at the Waco plant.

They consulted with the two area hospitals, Hillcrest Baptist Medical Center and Ascension Providence Hospital, for mask requirements, learning masks needed 80 percent of particulates filtered out. The employees tried a couple of pattern options, before picking the most efficient one that formed to the face without needing a pleat. It only has two pieces, with a notch at top and bottom and a layer of white felt in between.

“We looked at the different type of material that could do that,” plant manager Brandon Collins said. “We felt the three layers with the felt in the middle would give protection.”

After settling on a pattern, the crew came up with a social distancing strategy for the mask making. Cheryl Watson cuts the fabric and drops off the mask patterns and elastic at the Waco facility. The sewers then pick up the material and drop off completed masks.

Cheryl Watson measures cap and gown fabric for hospital masks at the Waco letter jacket facility. While the shelter-in-place order is in effect in McLennan Country, Waco plant employees are volunteering to create masks for local hospitals. Photo by Amanda Reynolds

“It’s not possible without a specific type of skills,” Collins said. “Sewing, it’s a dying art, and we happen to have some really experienced and hard-working people at our facility. I’m just impressed with their ability to take this one and contribute in a positive way.”

The experienced sewers can finish the masks quickly; it takes five to six minutes per mask. Three employees are sewing anywhere from 25 to 50 masks a day.

“I was so happy they were willing to do it,” Collins said. “Everyone was looking for a way to help. This is a testament to the type of people, the type of employees we have, that they still want to help. The fact that they’re volunteering, looking for more and more ways to help is my favorite part of this.”

In early April, Waco employees like Ana Lopez, switched from patch sewing to mask sewing. The women quickly transitioned to working from home, only coming up to the plant occasionally to drop off finished masks and pick up cut material and elastic. Photo by Amanda Reynolds

By the end of the first week, hundreds of masks had accumulated at the Waco facility. Collins dropped off the first batches last week, which included some of the women’s initial creations.

“The ladies had already started on some of them, so there were some with the Dallas Cowboys fabric and flowery fabric,” Mason said. “There were some cute ones in there with the plain blue fabric.”

Even the maintenance crew is pitching in. Edgar Zapata, who often fixes machines at the plant, has been visiting the sewers at home. When Lopez’s machine broke last week, Zapata went to her house to fix it.

The effort is important to Mason, who worked in the medical equipment industry for 18 years. She was employed at Providence during the H1N1 crisis.

“It’s good to give back to the community,” Mason said. “It’s always good to protect the healthcare workers because they’re on the frontline.”

For Vaquero, who has worked for Balfour for 15 years, this was a way to help the community and give back to the company.

“I think that today is when we have to think about helping each other,” Vaquero said.